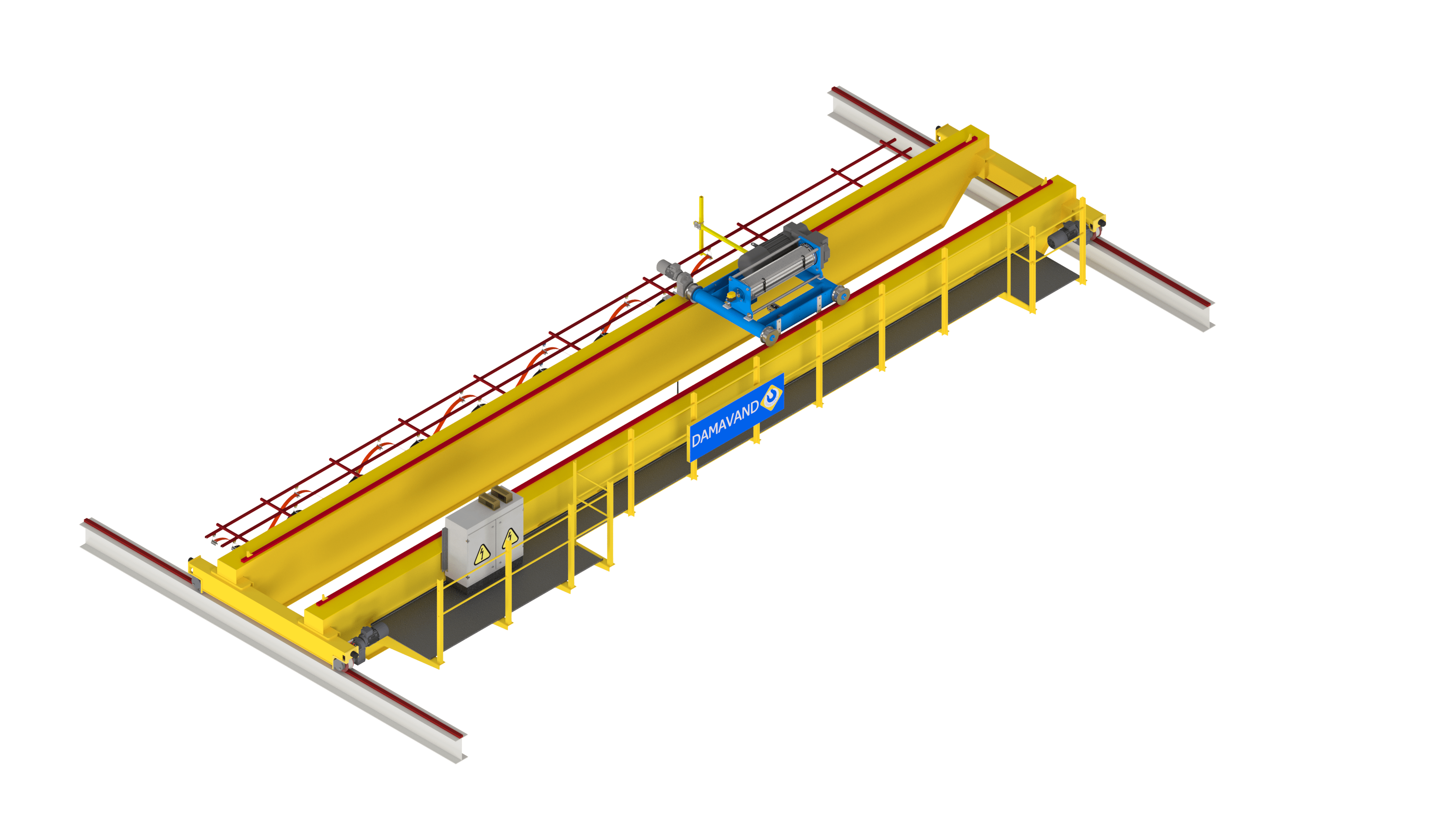

Double-girder overhead crane

Damavand designs and manufactures this type of crane, which can handle up to 2 to 200 tons and up to 50 meters in span. These cranes are generally divided into three categories: light, heavy, and super heavy. The crane structures are designed according to Din4132 and AWS D14-1 standards and are manufactured in equipped workshops according to the latest technology. The materials used in these cranes are S235JR-S275JR-S355JR. The double-girder overhead crane is effective in all industries. The advantages of this type of crane are a longer service life, greater adaptability to customer needs, and the ability to perform repairs faster and more easily.

What is a double-girder overhead crane?

A double-girder overhead crane is a type of crane that consists of two End carriages and two load-carrying beams (crane girders). In heavy and extra-heavy cranes, the number of load-carrying beams (crane girders) can be changed up to 4 according to the designer and customer needs. The shape and method of connecting these components varies depending on the conditions of the workshop, and the designer changes it according to the customer's needs. The winch in this type of crane moves on 2 rails located on the top of the crane girders. Considering the height of the crane girder rails to the ceiling of the hall, light double-girder cranes are designed and implemented with two standard and special designs (Low headroom). Heavy and extra-heavy double-girder cranes require a stronger structure than other cranes, and sometimes up to 4 girders are considered for one crane to be able to carry extremely heavy loads. In total, double-girder cranes have six, eight, or twelve movements (6 functions, 8 functions, or 12 functions). Up and down movement of the lifting hook (2 functions), left and right movement of the lifting assembly on the girders (2 functions), and finally the movement of the entire assembly when moving back and forth along the hall and on the rails. This completes the six movements (6 functions). In heavy and extra heavy cranes, by using two winches on the crane, the number of crane movements can be increased to eight movements (8 functions) or twelve movements (12 functions). Combining these movements is possible with the help of designing electrical circuits in the crane's electrical panel.

Application of double-girder overhead crane

Double-girder cranes are used in most industries with different weight capacities and can produce up to 200 tons in general and up to 450 tons in custom-made. For this reason, the use of this type of crane is far greater than other types of cranes. Power plants, steel, petrochemical, automotive, and any industry that requires heavy lifting are where this type of crane is used. In recent years, Fara Tadbir Damavand company has demonstrated a wide range of applications of double-girder cranes by manufacturing double-girder cranes for various industries.

Types of double-girder Overhead Cranes

There are different types of double-girder overhead cranes. Depending on the structure and conditions of the hall, the type of connection between the girder and the End carriage can be different, and all of these will affect the design of a suitable double girder crane. The method of connecting the girder to the End carriage is determined by the designer and based on the customer's needs. Light overhead cranes usually consist of two girder beams with two End carriages and four wheels, which are mostly used in general and have a maximum capacity of up to 30 tons. In some medium-heavy industries, two girders with four-end carriages and eight wheels are used. The capacity of this type of crane reaches up to 100 tons. In the steelmaking industry, a type of double girder crane is used, which is known as a slewing End carriage crane. The slewing End carriage is actually the addition of another degree of freedom to the double-girder crane End carriage. In the metal rolling industry, there is a need to rotate the load for the proper arrangement of ingots and other products. In these cases, this special type is used, which can rotate up to 90 degrees. In some super-heavy industries, especially steelworks, they usually use overhead cranes with four girder beams, eight End carriages, and sixteen wheels. The capacity of this type of crane can reach up to 450 tons. In this type of crane, two completely separate winches are usually used on the crane and are mostly used to move molten ladles.

Double-girder overhead crane components

A double-girder overhead crane has three main parts: the winch assembly, the girder, and the End carriage. Each of these assemblies also has subassemblies. The hoist includes the motor, gearbox, wire rope, hook, etc. The girder assembly includes the girder beam, electrical panel, power lines, and other components. The End carriage also includes a metal structure, longitudinal movement wheels, motors, and shock absorbers. Each of these components is designed specifically according to the needs. The arrangement of the parts on the crane should be such that the best possible access is provided for periodic services.

Design of a double-girder overhead crane

Designing a double-girder overhead crane requires much engineering knowledge and experience. Calculating the forces applied to the girders, selecting the appropriate hoist, calculations related to choosing the wire rope, electrical and electronic calculations, etc. all come together to design this widely used product. In more specific cases, such as designing cranes suitable for hydropower plants and extremely humid environments, designing multi-piece cranes for ease of transportation and handling, designing slewing cranes and super-heavy cranes, the design of a double-girder overhead crane will become much more complex. We are proud that in the past years, we have produced and supplied various types of double-girder overhead cranes to the country's industry.

Installation of overhead double-girder cranes

After designing and manufacturing the crane, the final product is transported to the project site for installation. Damavand's assembly and commissioning team will assemble and install the crane at the desired location as soon as it arrives. This installation requires a high level of experience. The smallest error in installation can lead to irreparable accidents. Also, the long life and need for less maintenance of the crane itself are the result of a good and standard installation. To improve the quality and customer satisfaction and with a well-equipped and suitable workshop space, Damavand pre-assembles and pre-commissions all cranes at the factory before sending them to the customer to ensure the quality and accuracy of its product performance. After ensuring the quality, the manufactured product is loaded and to be sent for installation.

Repairs and maintenance of double-girder overhead cranes

After installation and commissioning, the crane requires maintenance and inspection at certain intervals. In cranes, various parts such as wire ropes, wheels, and motors must be inspected and maintained regularly. The crane structure must also be inspected at certain periods. This will increase the life of the crane and prevent damage and possible dangers. It is also necessary to observe this for electrical and electronic devices, shock absorbers, and girder wheels. Of course, every device needs repairs after a while. Usually, the majority of failures in cranes are related to consumable parts that must be replaced promptly. Also, parts usually break down due to improper use. Drives, gearboxes, electrical systems, etc. can lose their efficiency after a while for any reason. You can ensure that your crane is operating in good and safe condition by reading the crane repair and maintenance manual and performing timely inspection and maintenance in accordance with the standards and conditions stated in the manual.