Monorail Overhead Crane (Monorail)

Monorail cranes are widely used in industries because they can be used in any corner of the hall. Damavand designs and manufactures this type of crane from 1 to 5 tons and up to 40 meters in height. The structure of this crane can be straight, curved, or a combination of these. The crane structures are designed according to the Din4132 standard and the AWS D14-1 standard and are manufactured in equipped workshops according to the latest technology. The materials used in these cranes are S235JR-S275JR-S355JR. Since the movement path of this crane can be customized, even in an arched shape, it can be used everywhere. In monorails, the path is customized for the hall and the lift moves under the monorail. This crane is most commonly used in industries such as cement and steel, which require cranes to move and overhaul equipment for major production machines.

What is a monorail overhead crane?

As the name suggests, this crane has a rail. This crane consists of a beam (rail) and a hoist. This crane is considered a light type and is used for indoor spaces. In this type of crane, the winch is usually installed under the girder and moves along it. Monorail cranes have a maximum of four movements (4 functions); up and down movement of the lifting hook (2 functions), left and right movement of the lifting winch (2 functions). The combination of these 4 movements is possible with the help of the design of electrical circuits in the crane's electrical panel.

Application of Monorail Overhead Crane

The design of the monorail overhead crane has made it very practical. The ability to design the path in this type of crane has made it play a very important role in production lines. The monorail can lift objects and transport them in production lines. This crane is usually used to move repetitive loads (such as moving parts in production lines). Monorail overhead cranes can be found in abundance in automotive, petrochemical, metal, polymer industries, warehouses, etc. production lines. Most of these cranes are classified as repair cranes and are used during overhauls or major repairs in large industries.

Types of Monorail Overhead Cranes

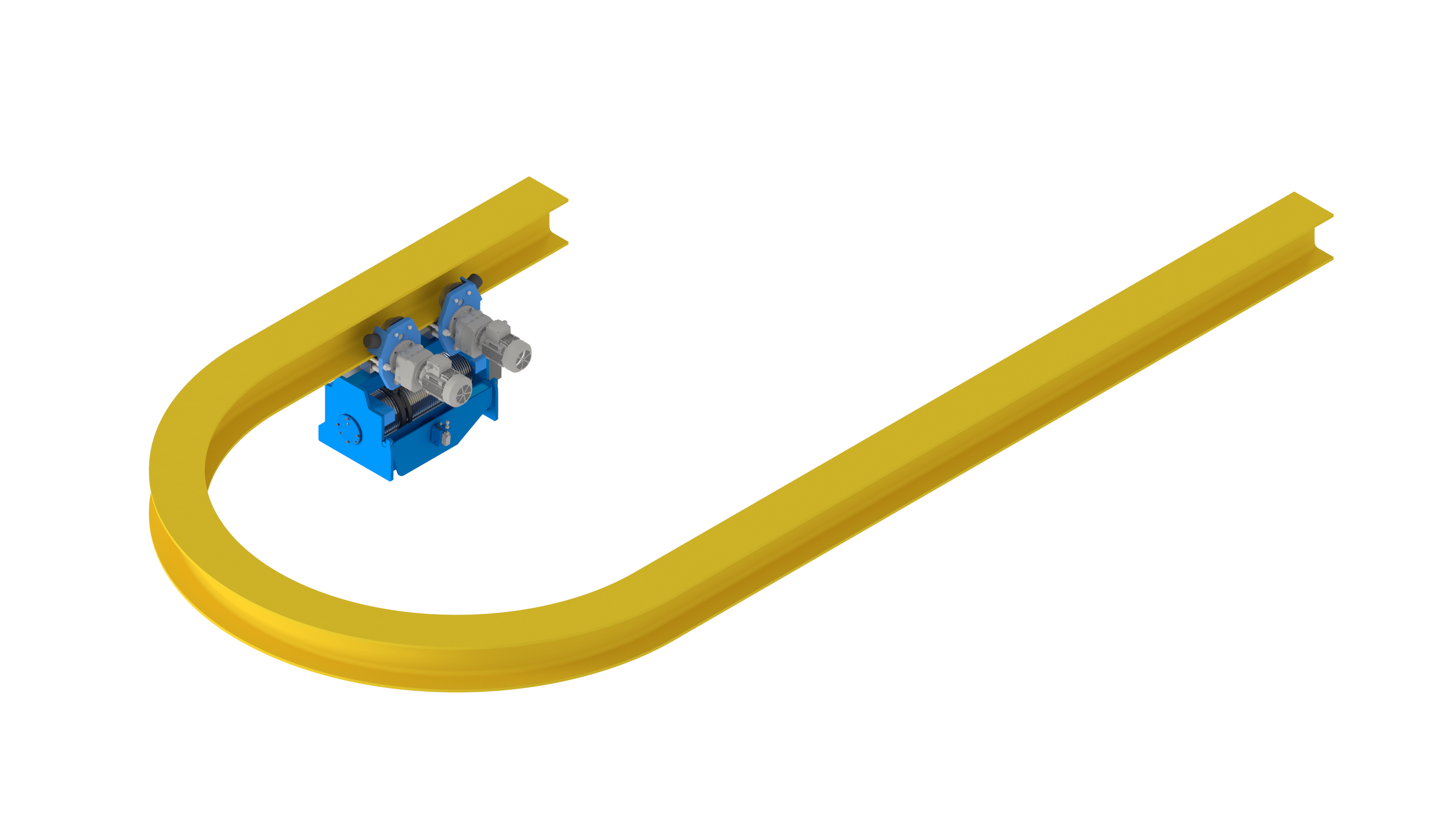

Monorail overhead cranes can be classified into two categories. The first category is the straight travel path and the second category is the curved travel path. It is also possible to combine the two, which is done according to the customer's needs and the designer's opinion.

Monorail overhead crane components

The structure of the monorail crane is very simple and has a few components that can be divided into two parts. The first part includes the winch and the second part includes the girder beam. The beam can be installed on ground columns or hung from the ceiling of the hall.

Monorail overhead crane design

What is most important and considered in the design of a monorail crane is the design of the beam or rail. After the beam is designed, calculations and selection of the appropriate hoist and wheel are considered. The design of the beam and the path of movement of the load is very dependent on the space of the desired hall. In production lines, to design a monorail overhead crane, the production process is examined, and based on the type of load that the monorail crane is supposed to move, the type of hoist is determined and its rail is designed. In rail design, the position of the equipment to be moved and the shape of the rail path are important. In designing a monorail crane, attention should be paid to the way the beam is connected to the ceiling, especially in relation to concrete structures.

Installation of Monorail Overhead Crane

After designing and manufacturing the crane, the final product is transported to the project site for installation. Damavand's assembly and commissioning team will assemble and install the crane at the desired location as soon as it arrives. This installation itself requires a high level of experience. The smallest error in installation can lead to irreparable accidents. Also, the long life and need for less maintenance of the crane itself are the result of a successful and standard installation. In order to improve quality and customer satisfaction and by having a well-equipped and suitable workshop space, Damavand pre-assembles and pre-commissions all cranes at the factory before sending them to the customer to ensure the quality and accuracy of its product performance. After ensuring the quality, the manufactured product is loaded and sent for installation.

Repair and maintenance of monorail overhead cranes

After installation and commissioning, the crane requires maintenance and inspection at certain intervals. In cranes, various parts such as wire ropes, wheels, and motors must be inspected and maintained regularly. The crane structure must also be inspected at specific periods. This will increase the life of the crane and prevent damage and potential hazards. This is also necessary for electrical and electronic devices, shock absorbers, and girder wheels. Of course, every device needs repairs after a while. Usually, most of the breakdowns in cranes are related to consumable parts that must be replaced promptly. Also, parts usually break down due to improper use. Drives, gearboxes, electrical systems, etc. can lose their efficiency after a while for any reason. You can ensure that your crane is operating in good and safe condition by reading the crane repair and maintenance manual and performing timely inspection and maintenance in accordance with the standards and conditions stated in the manual.