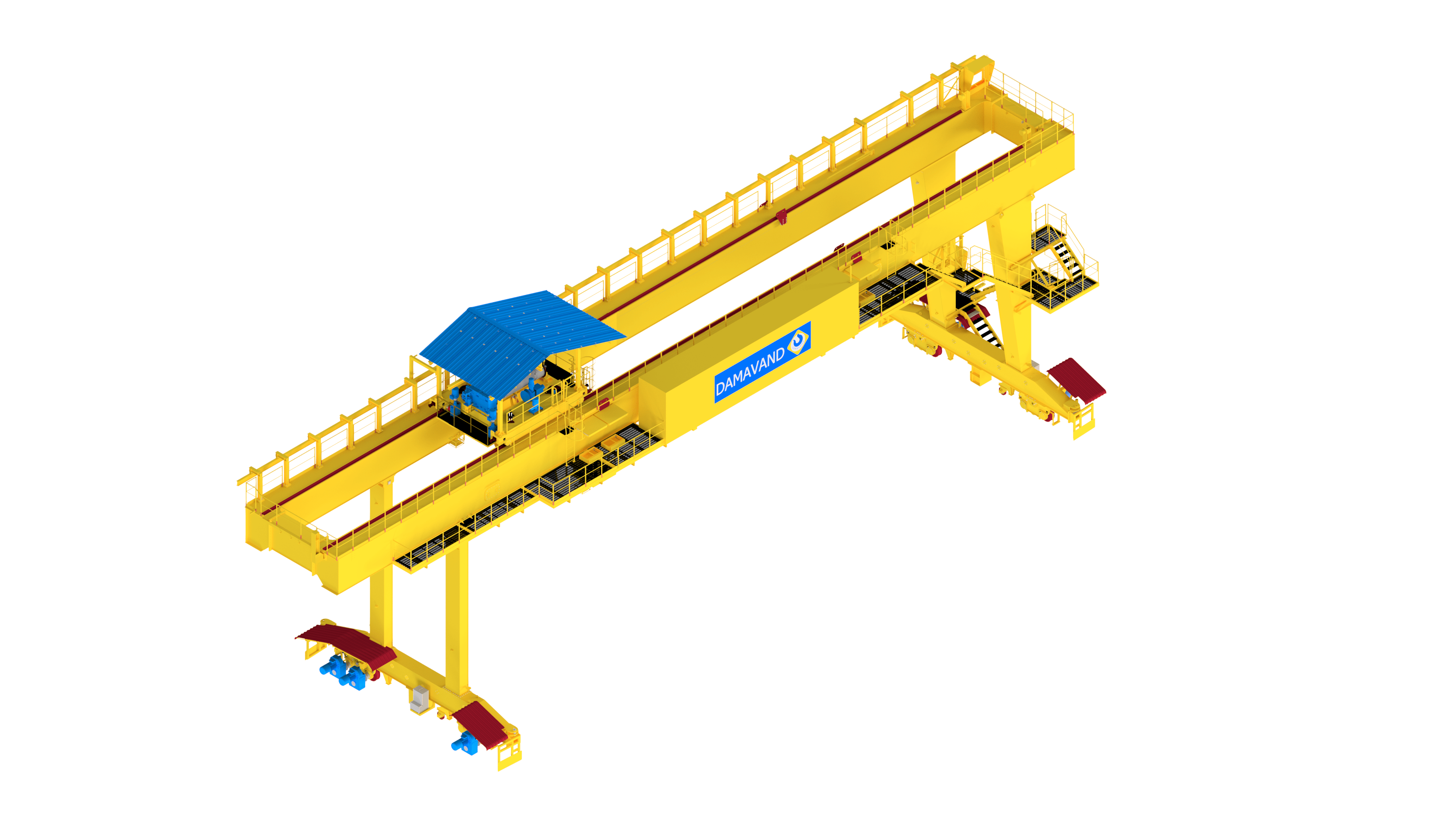

Gantry crane

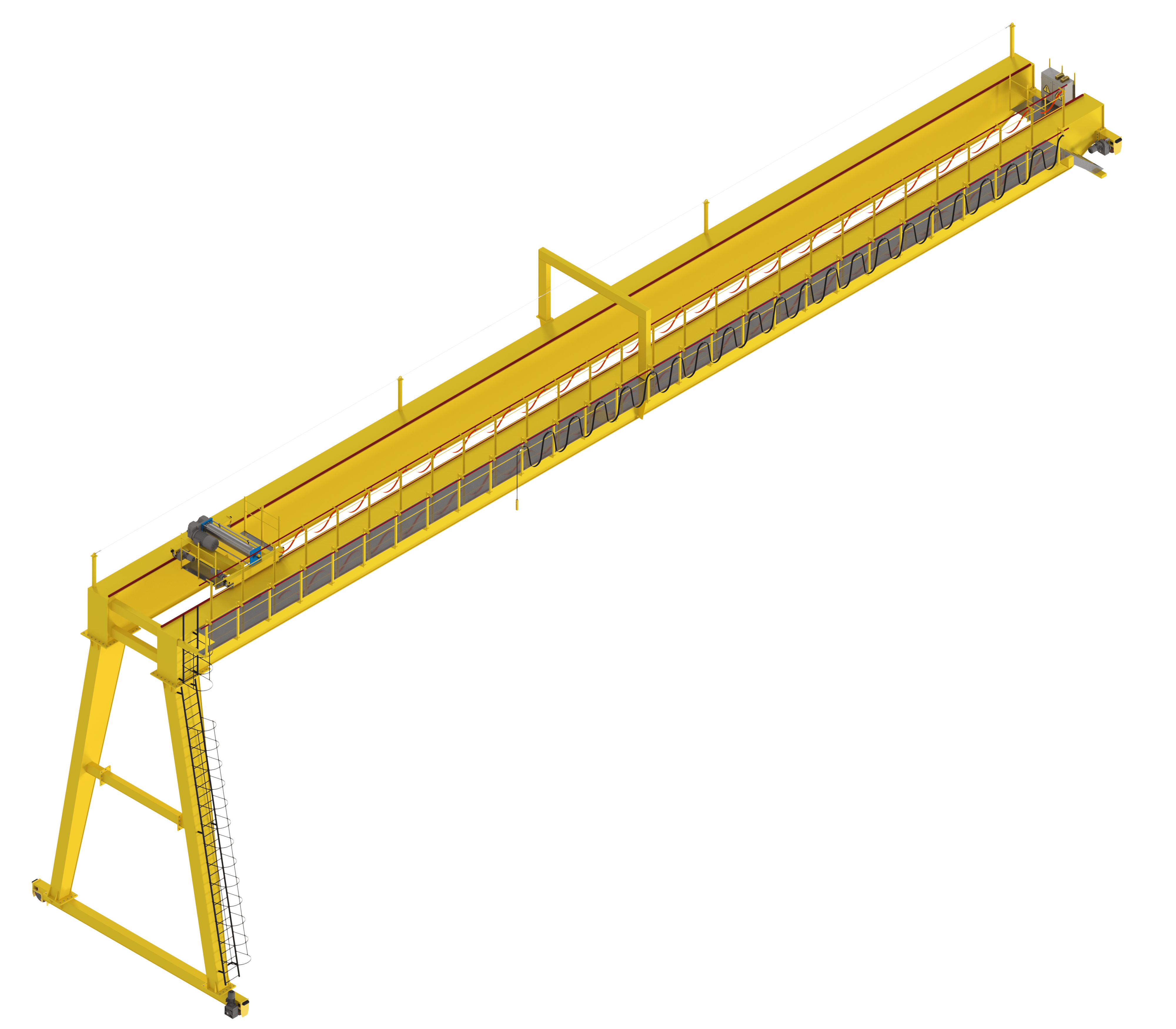

Semi Gantry crane

This type of crane can be designed and manufactured from 2 to 80 tons in tonnage and 6 to 40 meters in span with consoles on both sides as a pair of girders and a single girder. The most important feature of these cranes is their use in open environments. The crane structures are designed according to the Din4132 and AWS D14-1 standards and are manufactured according to the latest technology in equipped workshops. The materials used in these cranes are S235JR-S275JR-S355JR. Gantry cranes are the best choice for open spaces. Also, for spaces where the hall structure cannot install a lift or where a lift is needed that is not dependent on the hall structure and, in other words, is independent of the hall; a gantry crane can be used. The movement of this crane is on ground rails. Due to the independence of this type of gantry crane from the hall structure, this crane is of great interest to various industries, including shipping, mining, and open-air warehouses.

What is a gantry crane?

A gantry crane is a type of double-girder or single-girder crane that moves on rails installed on the ground by means of four columns. This crane consists of two End carriages and four columns along with two girder beams in the double-girder type or one girder beam in the single-girder type. The shape and method of connecting these components vary depending on the conditions of the workshop and the designer changes it according to the customer's needs. In terms of girder structure, a gantry crane is very similar to double-girder and single-girder overhead cranes. The difference between this type of crane is that it has columns. This type of crane generally has six movements (6 functions); up and down movement of the lifting hook (2 functions), left and right movement of the lifting winch (2 functions), and backward and forward movement of the entire crane girder along the length of the hall (2 functions). The combination of these 6 movements is possible with the help of the design of electrical circuits in the crane's electrical panel.

What is a half-gantry crane?

A half-gantry crane is a combination of a gantry and an overhead crane. In this type of crane, one End carriage, like an overhead crane, is on the hall carrier beam and the other End carriage, like a gantry crane, is on the ground. The application of a half-gantry crane is when part of the hall needs to be covered by a hoist. A half-gantry crane is a combination of a gantry and an overhead crane. In this type of crane, one End carriage, like an overhead crane, is on the hall carrier beam and the End carriage. This crane consists of two End carriages and two columns along with two girder beams in the double girder type or one girder beam in the single girder type. The shape and method of connecting these components vary depending on the conditions of the workshop and the designer changes it according to the customer's needs. The half-gantry crane is very similar in girder structure to double-girder and single-girder overhead cranes. This type of crane generally has six movements (6 functions); up and down movement of the lifting hook (2 functions), left and right movement of the lifting winch (2 functions), and back and forth movement of the entire crane girder along the length of the hall (2 functions). The combination of these six movements is possible with the help of the design of electrical circuits in the crane's electrical panel.

Application of gantry and half-gantry cranes

One of the applications of this crane is when the hall is changed and the loading capacity and overhead cranes in the hall are not sufficient for the new operation. Accordingly, a gantry crane of any capacity can be used by implementing a foundation on the floor of the hall. This has made this crane a popular choice for shipping and ports. In addition, gantry cranes can be installed outside the halls, at the entrance to the halls, and inside the halls; therefore, they appear in use with much less restriction than other cranes. The half-gantry type is also installed inside and outside the halls, due to its structure. This type is the best option for halls that are very wide but do not need to use the crane across their entire width

Types of Gantry Cranes

Gantry and half-gantry cranes have two main categories: simple type and cantilever type. Each of these two categories also has two types: single-girder and double-girder. A simple gantry crane is the same overhead crane with two columns at the beginning and end. The girder of a cantilever gantry crane extends beyond the columns on one or both sides. This model is used in cases where lateral movement is required beyond the range of the crane, such as loading ships in ports, or mines and warehouses. The foundation section is designed and implemented for installing rails based on the capacity of the crane.

Components of a gantry and half-gantry crane

Given the great similarity in the structure of a gantry crane and a single girder and double girder overhead crane, their components are also very similar. This crane has four main parts: winch, girder, column, and End carriage. The carriage and hoist section includes the motor, gearbox, wire rope, hook, and other related components. The girder section includes the girder beam, switchboard, and electrical components, walkway. The third section is the crane columns that connect the girders to the End carriage. The last section is the End carriage which sits on the ground and has wheels, bumpers, and actuators on it. Other ancillary equipment such as cable reels, anti-collision shields, equipment canopies, etc. are considered to be other ancillary parts of this group of cranes.

Gantry Crane Designing

The design of this type of crane is very similar to the overhead crane, except that the length of the End carriages is much longer. The design of the columns is also added to it. The design of the columns is very important because they bear a lot of load. Also, considering the movement of the entire set and the fact that the crane is not tied anywhere except the columns, it is essential to control the forces. The design of the half-gantry crane is also a combination of an overhead and a gantry crane, which has its points. The auxiliary equipment in the design of gantry cranes and also the method of powering the crane are among the things that must be considered in the design.

Installation of gantry and half-gantry cranes

After the crane is designed and manufactured, the final product is transported to the project site for installation. The assembly and commissioning team of Damavand Company will assemble and install it at the desired location as soon as the crane arrives. This installation requires a high level of experience. The smallest error in installation can lead to irreparable accidents. Also, the long life and need for less maintenance of the crane itself are the result of a successful and standard installation. To improve the quality and customer satisfaction and with a well-equipped and suitable workshop space, Damavand pre-assembles and pre-commissions all cranes at the factory before sending them to the customer to ensure the quality and accuracy of its product performance. After ensuring the quality, the manufactured product is loaded and sent for installation.

Repairs and maintenance of gantry and semi-gantry cranes

Cranes, like all industrial equipment, require periodic care and maintenance. This maintenance ensures the health of the device and its maximum productivity. Checking the health of the electrical system, wire ropes, actuators, shock absorbers, and other components of the device is included in the maintenance program. Of course, if proper and timely maintenance is not carried out, we may see the need for heavy repairs. There is also a possibility of life and financial risks.