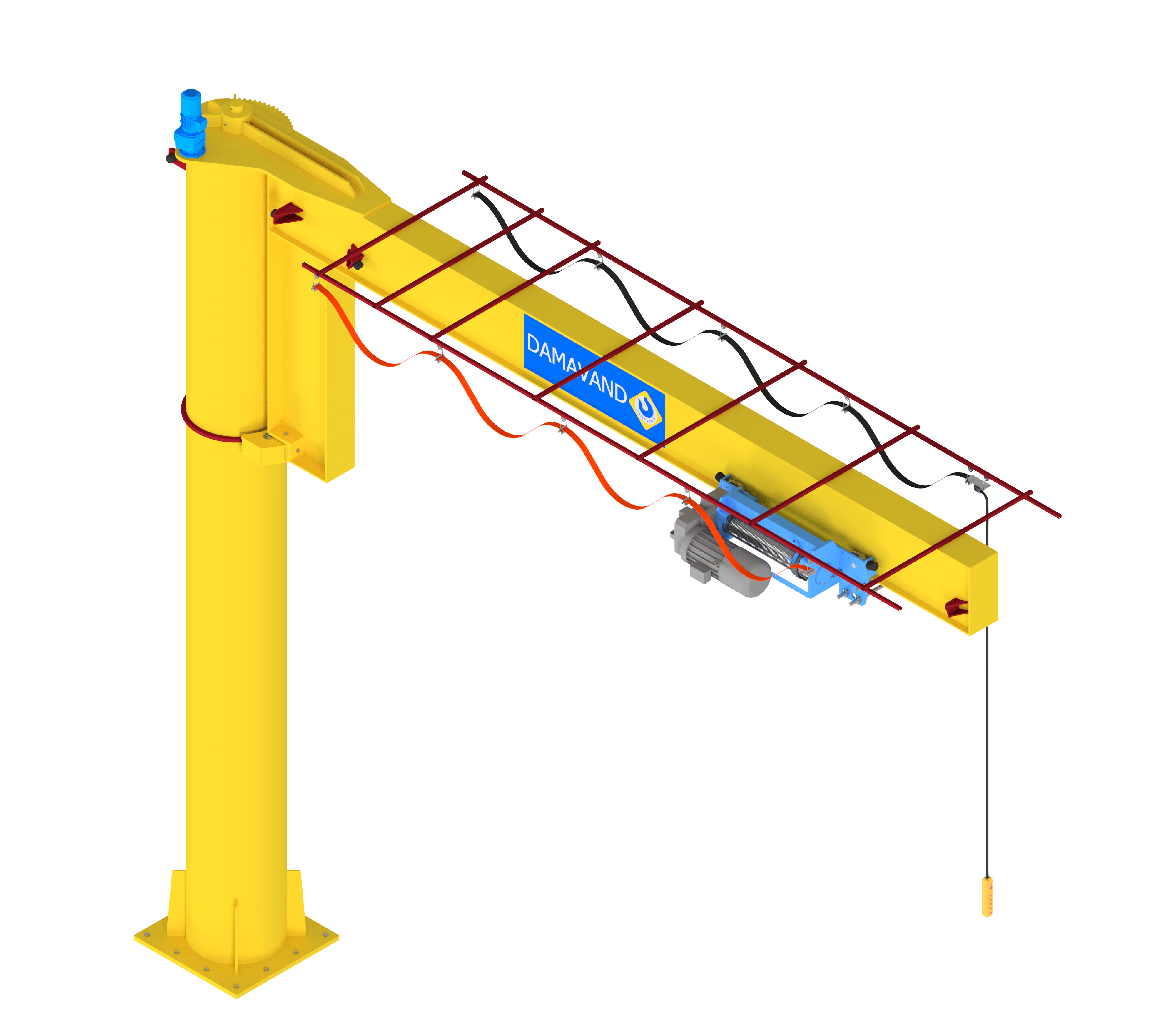

Jib crane

This type of crane is manufactured for use in assembly lines, warehouses, and machinery stations. Damavand designs and manufactures this type of crane from 1 to 8 tons and up to 8 meters of arm length. The height of the column in this type of crane depends on the customer's needs, which is designed based on the conditions. Generally, this crane is used in light industries, but sometimes in heavy industries, especially steel industries, it is also used locally to move ancillary parts. The crane structures are designed according to the Din4132 and AWS D14-1 standards and are manufactured according to the latest technology in equipped workshops. The materials used in these cranes are S235JR-S275JR-S355JR. The advantages of these types of cranes are their lower price and the possibility of quick and easy installation in halls and also in closed environments such as warehouses and basements. The limitation of using these cranes is only the possibility of implementing their foundation in the hall bed, which must be estimated and feasibility assessed in terms of dimensions with the designer's opinion

What is a jib crane?

A jib crane consists of a column and a load-bearing beam (arm) as well as two steel wheels, which rotate around the column axis by a gearbox motor and cover a circular area with a radius of the arm length and centered on the crane column. This arm can rotate from 180 to 360 degrees around the column axis. In this type of crane, the winch is usually installed under the girder in a hanging position or next to the girder in a hanging position (low headroom) and moves along the arm. This type of crane is widely used in industry and is widely used in sheds and places where it is not possible to use overhead cranes or monorails, docks, basements, and warehouses. In terms of ease of installation, this crane is very popular; but the length of the arm in this crane has limitations. Jib cranes have a maximum of six movements (6 functions); Up and down movement of the lifting hook (2 functions), left and right movement of the lifting winch (2 functions), and back and forth movement of the entire crane girder along the length of the hall (2 functions). The combination of these 6 movements is possible with the help of the design of electrical circuits in the crane's electrical panel.

Application of jib cranes

Due to the weight capacity of this type of crane, they are usually used in workshops for packaging and assembling heavy parts, welding workshops and manufacturing parts, etc. Jib cranes are the best option for moving parts in workshops. Usually, this crane is used to move loads for one or two machines that are installed nearby. Usually, this type of crane is low-load. Of course, it is possible to design and produce high-load types depending on the need. In some steelmaking industries, such cranes are used in the preparation of ladles in the preheating and post-heating sections or the replacement of refractories.

Types of Jib Column Cranes

Jib cranes fall into two general categories. Cranes that have an independent column so that the column is installed on a foundation at the work site and the arm and winch are installed on it. The second type has the arm and winch connected to one of the columns in the hall. The difference between these two types is that in the first type, the crane beam can rotate 360 degrees, but in the second type, the maximum beam can rotate 180 degrees. Other factors that create diversity in jib column cranes include special cases where the beam or girder is designed as a backbreaker, as well as cases where, based on the amount of rotation of the crane, the column is designed with a circular or cross-sectional section.

Jib Crane Components

The design of jib cranes is directly dependent on the amount of load to be moved. In this type of crane, the length of the beam in the standard state cannot exceed 8 meters. Based on the type of use and the amount of load, the length of the beam must be carefully calculated and designed in the optimal state. In the design of this type of crane, engineering calculations related to the foundation are also significant.

Design of a jib crane

The design of a jib crane is directly dependent on the amount of load it is intended to move. In this type of crane, the length of the beam in the standard state cannot exceed 8 meters. Based on the type of use and the amount of load, the length of the beam must be carefully calculated and optimally designed. If accurate calculations and design are not made, the possibility of danger during use will be very high.

Installation of jib crane

After designing and manufacturing the crane, the final product is transported to the project site for installation. Damavand's assembly and commissioning team will assemble and install the crane at the desired location as soon as it arrives. This installation itself requires a high level of experience. The smallest error in installation can lead to irreparable accidents. Also, the long life and need for less maintenance of the crane itself are the result of a successful and standard installation. To improve quality and customer satisfaction and by having a well-equipped and suitable workshop space, Damavand pre-assembles and pre-commissions all cranes at the factory before sending them to the customer to ensure the quality and accuracy of its product performance. After ensuring the quality, the manufactured product is loaded and sent for installation.

Repair and maintenance of jib cranes

After installation and commissioning, the crane requires maintenance and inspection at certain intervals. In cranes, various parts such as wire ropes, wheels, and motors must be inspected and maintained regularly. The crane structure must also be inspected at specific periods. This will increase the life of the crane and prevent damage and potential hazards. This is also necessary for electrical and electronic devices, shock absorbers, and girder wheels. Of course, every device needs repairs after a while. Usually, most of the breakdowns in cranes are related to consumable parts that must be replaced promptly. Also, parts usually break down due to improper use. Drives, gearboxes, electrical systems, etc. can lose their efficiency after a while for any reason. You can ensure that your crane is operating in good and safe condition by reading the crane repair and maintenance manual and performing timely inspection and maintenance in accordance with the standards and conditions stated in the manual.