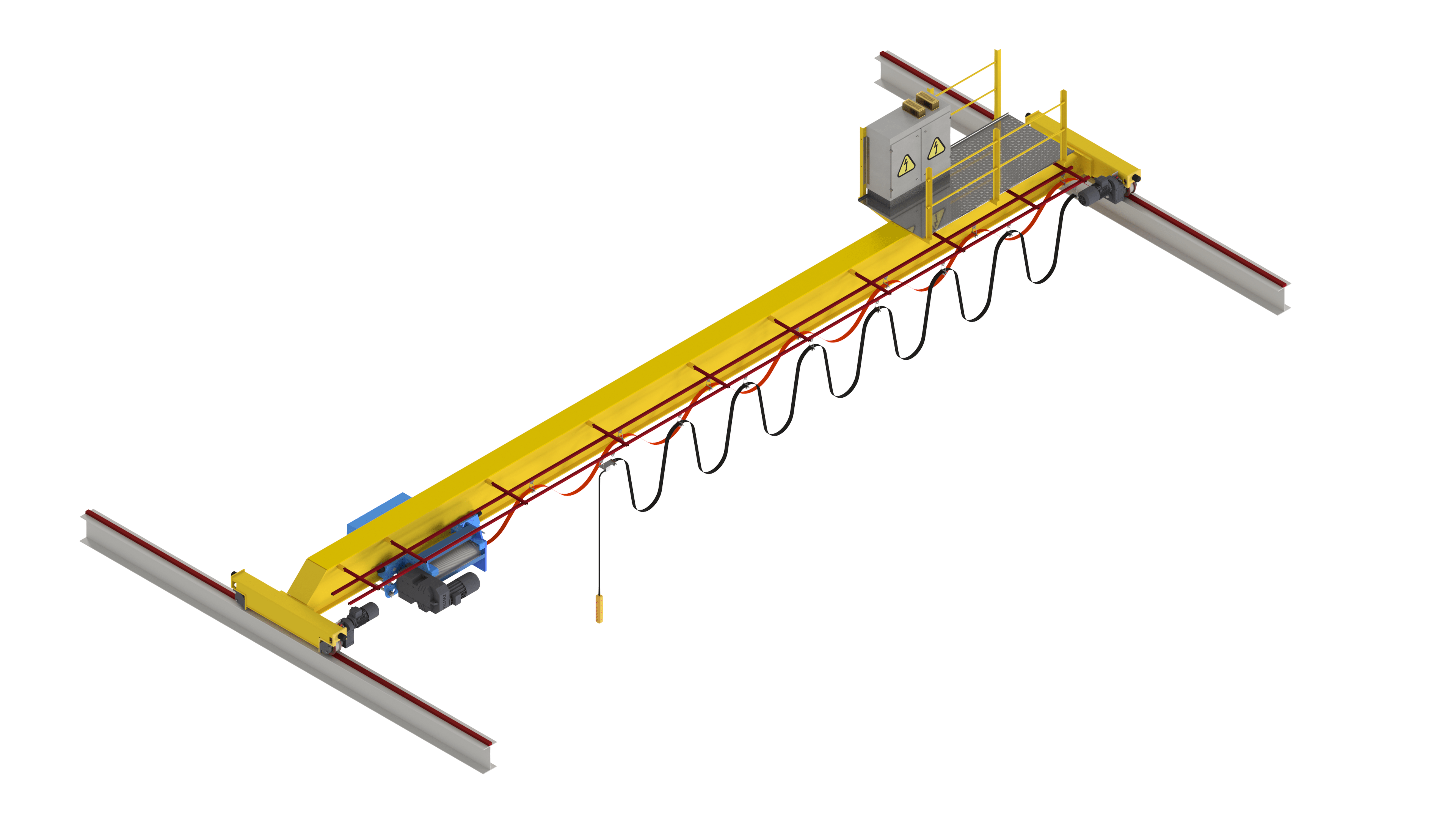

Single-girder overhead crane

Damavand designs and manufactures cranes in this category, ranging from 1 to 12 tons and up to 30 meters in span. The structure type of this crane can be implemented as a Monorail, Single girder, or Suspension. Crane structures are designed according to the Din4132 standard and AWS D14-1 standard and are made according to the latest technology in equipped workshops. The materials used in these cranes are S235JR-S275JR-S355JR. Usually, the advantages of this type of crane are the low price, light weight of the structure, smaller dimensions, and ease of installation.

What is a single-girder overhead crane?

A single-girder overhead crane is a type of overhead crane that consists of two Carriages and one load beam (crane girder). The form and method of connecting the girder to the conductor varies according to the conditions of the workshop, and the designer changes it according to the customer's needs. In this type of crane, the winch is usually suspended under the girder or next to the girder (low head room) and moves along it. The conductors move on the hall rails utilizing at least four steel wheels (Girder), usually two driving wheels (with gearbox) and two moving wheels. The number of crane wheels, both driving and moving, depends on the conditions of the workshop and the design made by the crane designer. Structurally, single-girder and double-girder overhead cranes are very similar; But there are also fundamental differences that result from the specific uses of each. Single girder overhead cranes have a maximum of six movements (6 functions): up and down movement of the lifting hook (2 functions), left and right movement of the lifting winch (2 functions), and back and forth movement of the entire crane girder along the length of the hall (2 functions). The combination of these 6 movements is possible with the help of electrical circuit design in the crane switchboard. Crane carriage

Application of single-girder overhead crane

Single-girder overhead cranes have a lower lifting capacity compared to double-girder cranes. Therefore, they are suitable for halls, small workshops and warehouses. However, this does not mean that this equipment cannot be used in large halls; due to the smaller dimensions of the lift, this crane will have many applications. Usually, in heavy industries, single-girder cranes are used as a supplement to the main crane and to perform ancillary services and line maintenance and repair. In many cases, installing a single-girder crane (monorail) under the ceiling of heavy industrial halls allows for better repairs and maintenance on super-heavy double-girder cranes.

Types of Single-girder overhead cranes

Single-girder overhead cranes usually move on the hall's girder. The important point in these cranes is that the hoist moves under the girder; this is very important in height calculations. The design of the girder connection to the End-Carriage also depends very much on the hall conditions. Considering the hall's structure and conditions, the type of girder connection to the End-carriage can have 9 different modes. In the design of these cranes, the safety and accessibility of the crane repairmen should be paid attention to as much as possible, and the safety of the repairmen should be taken into account in the calculations and drawings.

Single-girder overhead crane components

A single-girder overhead crane has three main parts: the winch assembly, the girder, and the End carriage. Each of these assemblies also has subassemblies. The hoist includes the motor, gearbox, wire rope, hook, etc. The girder assembly includes the girder beam, electrical panel, power lines, and other components. The End carriage also includes a metal structure, longitudinal movement wheels, motors, and shock absorbers. Each of these components is designed specifically according to the needs. The arrangement of the parts on the crane should be such that the best possible access is provided for periodic services.

Single-girder overhead crane design

Designing a single-girder crane, like other cranes, requires a lot of experience and technical knowledge, especially if the dimensions and weight capacity are greater than the standard. Fara Tadbir Damavand company, one of the most experienced manufacturers of custom cranes in the country, has been able to provide its technical knowledge and experience to the country's industry over the past years. Most of the Single-girder cranes manufactured by Fara Tadbir Damavand have been customized and special. Going beyond the standard limits requires high calculations and manufacturing strength; a power that Fara Tadbir Damavand has.

Installation of overhead single-girder cranes

After designing and manufacturing the crane, the final product is transported to the project site for installation. Damavand's assembly and commissioning team will assemble and install the crane at the desired location as soon as it arrives. This installation requires a high level of experience. The smallest error in installation can lead to irreparable accidents. Also, the long life and need for less maintenance of the crane itself are the result of a good and standard installation. To improve the quality and customer satisfaction and with a well-equipped and suitable workshop space, Damavand pre-assembles and pre-commissions all cranes at the factory before sending them to the customer to ensure the quality and accuracy of its product performance. After ensuring the quality, the manufactured product is loaded and to be sent for installation.

Repairs and maintenance of single-girder overhead cranes

After installation and commissioning, the crane requires maintenance and inspection at certain intervals. In cranes, various parts such as wire ropes, wheels, and motors must be inspected and maintained regularly. The crane structure must also be inspected at certain periods. This will increase the life of the crane and prevent damage and possible dangers. It is also necessary to observe this for electrical and electronic devices, shock absorbers, and girder wheels. Of course, every device needs repairs after a while. Usually, the majority of failures in cranes are related to consumable parts that must be replaced promptly. Also, parts usually break down due to improper use. Drives, gearboxes, electrical systems, etc. can lose their efficiency after a while for any reason. You can ensure that your crane is operating in good and safe condition by reading the crane repair and maintenance manual and performing timely inspection and maintenance in accordance with the standards and conditions stated in the manual.