Brakes

Brakes are considered essential parts of cranes. Brakes are generally installed behind or in front of the motors. In heavy industry cranes, especially in cases where safety against falling loads is very important, brakes are also installed on the drum. The braking torque in cranes is usually considered to be between 3 and 6 times more than the motor torque. All types of brakes on the crane operate in the Normal close mode. Brakes are divided into two categories in terms of power supply: magnetic brakes and hydraulic brakes.

Types of Brakes

Magnetic Brake

The basis of this type of brake is the attraction of the brake plate towards a magnetic magnet, which causes the brake to open, and when braking, this plate is compressed by the pressure of several springs, which causes the brake disc to lock again. In general, this type of brake consists of a magnet, a brake disc, a spline coupling, and several springs. This type of brake is usually installed behind the motor and is produced in single-phase, two-phase, and three-phase types in terms of magnetic characteristics. The single-phase type of this type of brake is most commonly used in cranes due to its very low wear and tear on parts and better life and performance.

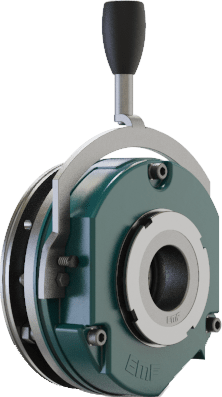

Hydraulic Brake (Hydro Brake)

The basis of this type of brake is a mechanical mechanism that is activated by the power from a hydraulic pump and the brake is released. Hydraulic brakes include shoes brake and Drum brakes, hydraulic pump motor (Thruster), and mechanical mechanism. This type of brake is divided into two categories in terms of mechanical mechanism: hydraulic brakes with disc mechanism and hydraulic brakes with bowl mechanism. The disc mechanism type has better performance, less depreciation, and smaller volume, but it is more expensive economically, and therefore, in heavy and semi-heavy industries, the bowl mechanism type is used more often.

Thruster Shoes Drum Brake

This brake is known as a safety brake in case of an accident is installed on the drum disc and only works when the load starts to fall for any reason. At this moment, the brake works with the help of very accurate tachometer sensors and locks the drum. This brake is considered a member of the hydraulic disc brake family but with several times more power. The high price of this brake, along with the mechanical, electronic, and electrical equipment related to it, has caused this brake to be used more in super-heavy cranes, especially in the steelmaking industry.