Wheel Block & End Carriage

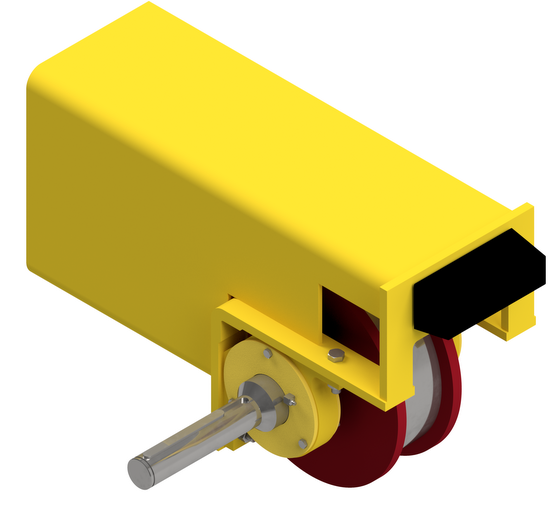

The End carriage is a part of the crane and consists of wheels and a metal chassis connecting them. The End carriages in the crane girder and the crane winch chassis have a completely similar function and with their help the crane will be able to move along the hall and the winch across the hall. If a gearbox is installed on the wheels, they are called driving wheels, and otherwise, they are called driven wheels. There are at least two driving wheels and two driven wheels in cranes. This number can be increased to sixteen wheel sets depending on the tonnage of the crane and the conditions considered by the designer. The material of the wheels is forged alloy steel and it is also possible to harden the wheel surface according to the need. The hardness of the wheel surface is to make the wheel resistant to wear and corrosion in contact with the rail.

Types of wheels

Crane wheels are divided into two general categories: driven (with motor and gearbox) and movable (without motor and gearbox). Another characteristic of the wheels is their diameter, which is determined by engineering calculations based on the load pressure tolerance, speed of movement, and width of the rail under the crane. Damavand Company has designed and produced a wide range of wheels to withstand pressure in different conditions. Based on this classification, the wheels are classified into types 130-160-180-200-250-280-315-400-500-600-710-800. The design and production of wheels outside the mentioned range are done according to the need. In the design of wheels, many things should be considered, including ease of wheel replacement and lubrication and inspection when necessary. In terms of structure, the wheels are divided into two categories: Wheel block and Open wheels.

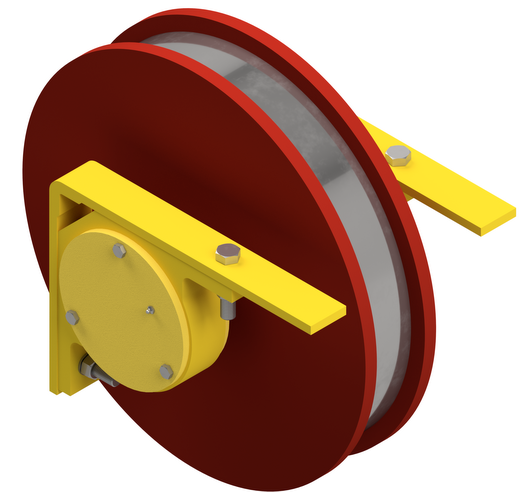

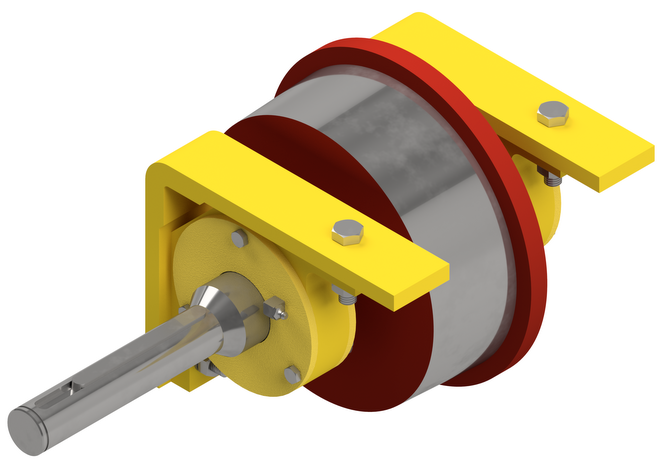

Wheel block

This type of wheel is mostly used in light-duty cranes. Their advantages are their simple design, easy maintenance and replacement, and low price. This type of wheel is produced in different sizes such as 130-160-180-200.

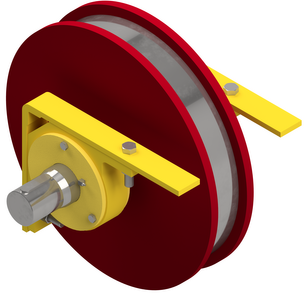

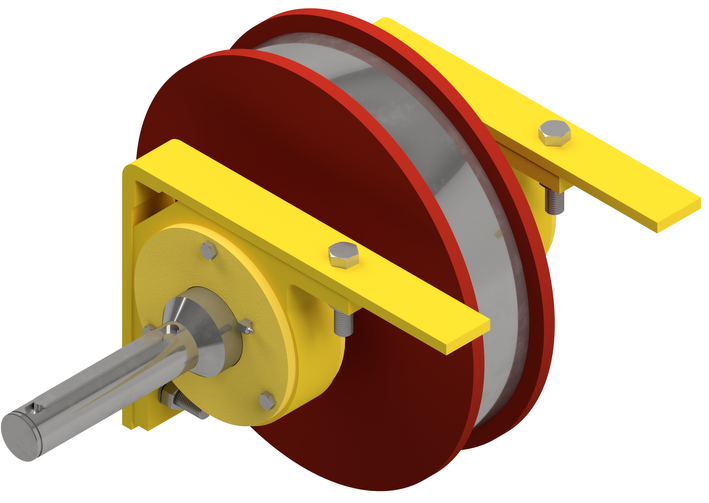

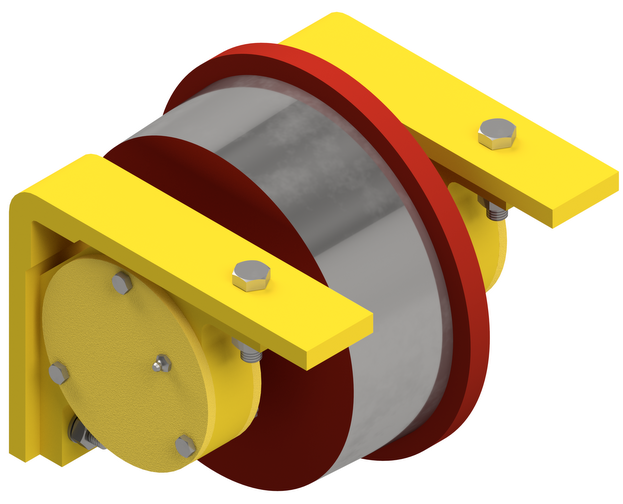

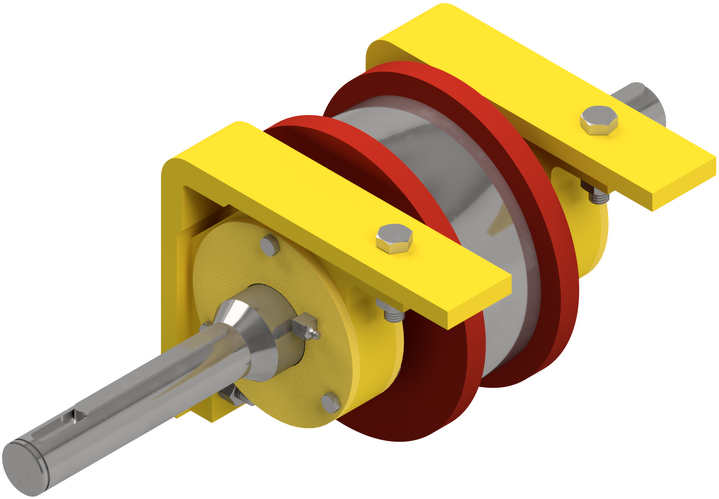

Open-wheel/ bearing wheels

These wheels are most commonly used in Damavand cranes. Their advantages include the following:

1. Very easy and fast service and maintenance

2. All wheel components are visible for periodic inspections

3. Ability to change the main components according to the limitations of the project site

4. Ability to install auxiliary equipment such as Rail sweeper, Buffer, and Anticollision

Damavand produces a full range of this product with sizes 160-180-200-250-315-400-500-600-710-800.