Winch

The main part of the crane is the winch, which is responsible for raising and lowering the load and moving it along the crane girder. The winch generally consists of a trolley chassis, wheels, hoisting motor gearbox, trolley, drum, hook, and other accessories. Winches are diverse and classified based on application, capacity, speed, and other factors. Winches are structurally divided into Standard single-girder and double-girder winches, Open and Rotating winches, and other special winches.

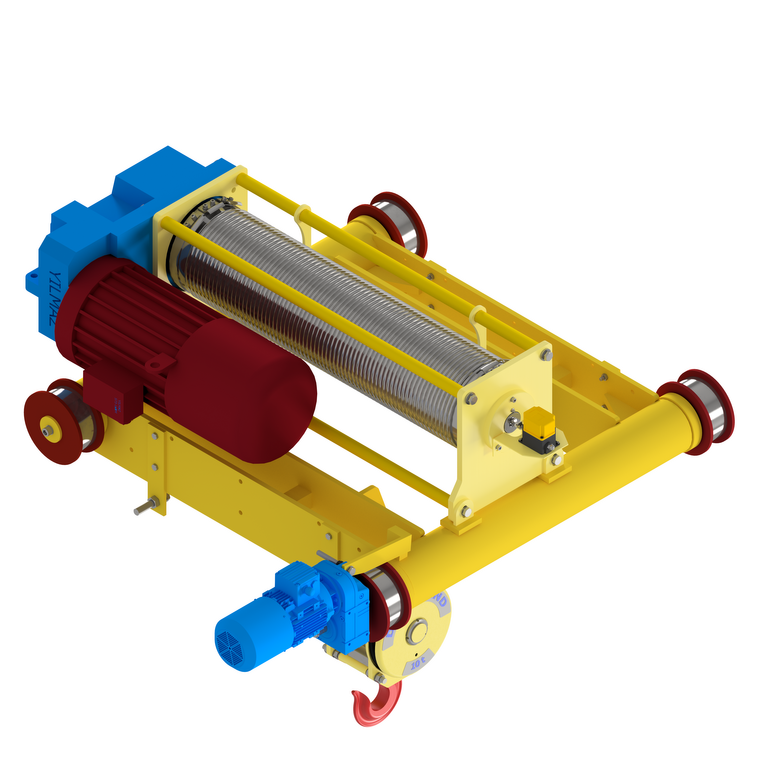

Close (Standard) Winches

These winches are mostly used for general applications such as warehouses and equipment manufacturing workshops, repair purposes, and other light applications. The single-girder type of these winches can be designed and manufactured from 1 to 12 tons and the double-girder type from 2 to 80 tons. Common advantages of this type of winch include small dimensions, low price, and ease of repair and maintenance.

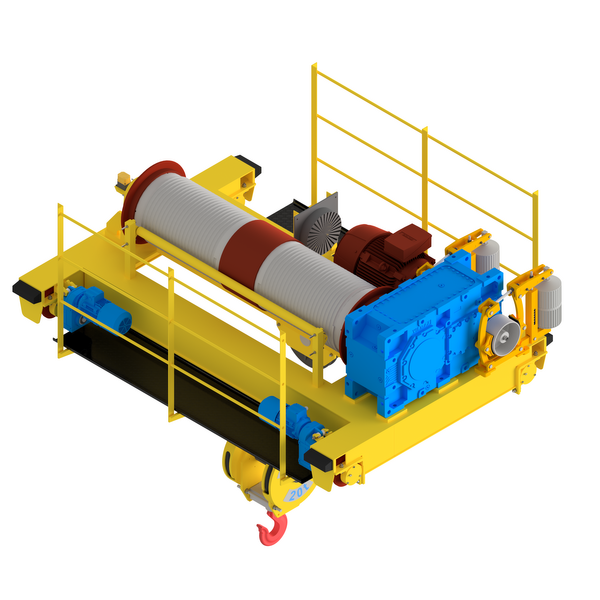

Open Winches

Most of this group of winches are used in heavy industries and environments where there is heat, dust, high working pressure, loads with a weight close to the crane's rated weight, and some other unfavorable working conditions. These winches must be designed and manufactured in such a way that they have the least possible damage and their repairs and inspections can be done quickly and easily. These winches can be designed and manufactured with a capacity of 10 tons to 200 tons. Open winches can have various designs, shapes, and dimensions depending on the working conditions.

Rotating Winches

This type of winch is in the Open winch category. The rotating winch is the addition of another degree of freedom to the double-girder crane. In the steel industry, and especially in warehouses, there is sometimes a need to rotate the load to arrange ingots and other products. In these cases, this special type is used, which can rotate up to 90 degrees. Usually, this type of crane has eight movements (8 functions).