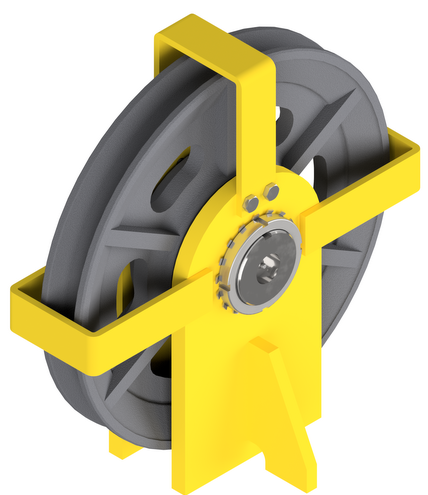

Idler Pulleys

Pulleys are part of the hook members. With the help of crane pulleys, designing a wide range of winches with different cargo speeds is possible. Each of these winches is suitable for a specific working group and specific applications. The basis for using Idler pulleys in cranes is the laws related to pulleys in physics. Idler Pulleys allows designers to provide consumers with several products with different side specifications and different uses based on one winch. In the design of pulleys, issues such as the proportion of the pulley diameter, the specifications of the rope groove, the diameter of the rope, the possibility of quick and easy replacement of pulleys, lubrication of bearings, and preventing the rope from exiting the pulley groove in emergencies should be considered.

Classification of Idler Pulleys

Idler pulleys are divided into several categories based on criteria such as pulley diameter, wire rope load capacity, pulley groove dimensions, etc. The number of pulleys in each winch is also a basis for their classification. Damavand Company provides a wide range of idler pulleys with different specifications and dimensions to its esteemed consumers. Generally, idler pulleys are divided into single pulley, double pulley, triple pulley, and quad pulley types in terms of the number of pulleys, and into types 190-260-315-400-570-670 in terms of dimensions. The design and production of pulleys outside the above categories are carried out according to the project. The method of installing the pulleys on the winch should also be considered when selecting, which are generally divided into two categories: mounted and suspended.